Spark arrestors, anti-vibration mounts, suspended sound-absorbing panels and wall and roof coverings: our range of accessories meets both standard and customized solutions for the control of noise, vibrations and other acoustic emissions in the industrial sector.

The following accessories for silencers complete our offer:

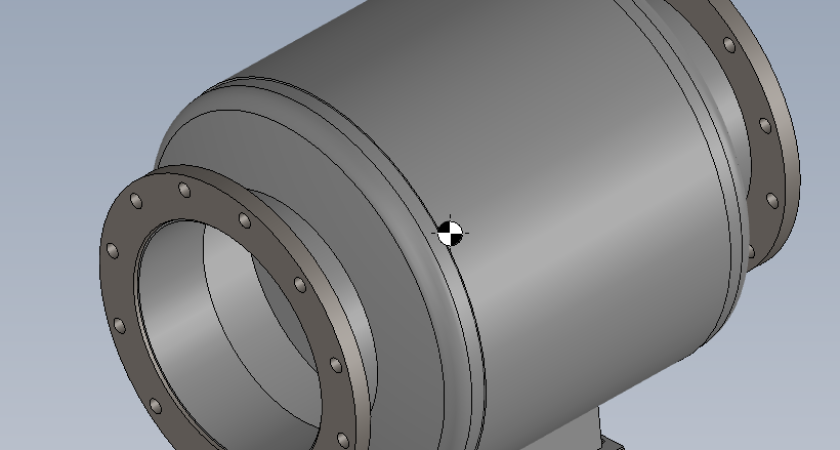

STOPSON spark arrestors prevent the emission of glowing particles from internal combustion engines, reducing the risk of fire. They can be supplied as stand-alone units or integrated into silencers. Based on centrifugal separation, they capture carbon particles larger than 0.023″ in diameter via deflectors or fixed blades. Available in cylindrical or disc versions, the latter offer greater thermal insulation, compact dimensions and the possibility of modulating the flow by adding discs.

STOPSON spark arrestors prevent the emission of glowing particles from internal combustion engines, reducing the risk of fire. They can be supplied as stand-alone units or integrated into silencers. Based on centrifugal separation, they capture carbon particles larger than 0.023″ in diameter via deflectors or fixed blades. Available in cylindrical or disc versions, the latter offer greater thermal insulation, compact dimensions and the possibility of modulating the flow by adding discs.

Anti-vibration mounts are mainly used to reduce structurally transmitted noise and vibration caused by mechanical systems and equipment.

The provision of suitable vibration isolation products is a critical factor in effectively reducing the transfer of noise and vibration from mechanical plants and equipment located in factories, ships, offshore platforms, offices, residential apartments, studios, theatres, auditoriums, schools and universities, hospitals and research laboratories.

Our range of anti-vibration mounts have been specially designed to provide optimal vibration isolation of a wide range of equipment used in various applications and if selected and installed correctly our anti-vibration mounts can reduce vibration transmission by over 95%.

Description and principle of operation

Baffles are used to reduce the reverberation of the sound of the industrial environment by sound absorption. They find their application in almost all environments with high reverberation, where there are multiple sources of noise of similar emission and especially in those crowded environments, without a specific location of personnel.

The panels are made by assembling an absorbent coating of unalterable, non-combustible and rot-proof mineral wool on a steel structure of unalterable, non-combustible and rot-proof mineral wool and can have a surface finish of corrugated aluminum sheet. To completely insulate the absorbent coating, it is protected by a plastic film. In addition, the steel frame of the panels is equipped with two supports, which are essential for their construction.

Protection

For standard systems, the support frame is obtained by machining “Sendzimir” galvanized sheets or with semi-polished and cold-rolled aluminum.

Two different variants are produced:

Accessories

The panels are equipped with:

Description and principle of operation

Wall coverings are used to reduce the reverberation of the sound of the industrial environment due to sound absorption. They find their application in almost all environments with high reverberation, where there are multiple sources of noise of similar emission and especially in those crowded environments, without a specific location of personnel.

The wall cladding is mounted on site with support beams, absorbent coatings, non-combustible and rock wool in rigid panels and has a surface finish of perforated galvanised sheets. To prevent dispersion into the environment, the absorbent coating is protected by a layer of fiberglass, typically black in color.

Protection

For standard systems, the support frame is obtained by processing “Sendzimir” galvanized sheets. The special version can be made of pre-painted light grey sheet steel or powder-coated sheet steel with specific RAL colour.

Accessories

Wall coverings are equipped with: